Phone +1 916 503 5343

Fax +1 916 244 0709

Business Inquiries

info@hexces.com

Employment Opportunities

hr@cleanenergysystems.com

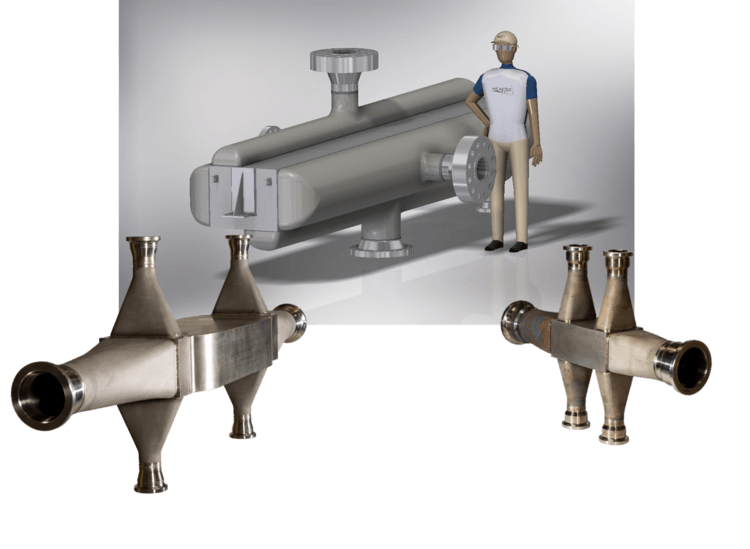

Compact Platelet Heat Exchangers – Innovative Thermal Management Solutions

HEXCES, a division of Clean Energy Systems, Inc., designs, develops, manufactures, and services compact platelet heat exchangers (CPHXs) for numerous market applications. These diffusion bonded heat exchangers, also known as printed circuit heat exchangers (PCHEs), or microchannel heat exchangers (MCHEs), provide high pressure, temperature, and thermal capabilities within a small footprint.

HEXCES’ heritage is directly traceable to the inception of the CPHX, developed in the aerospace industry in the mid-1970s, preceding the first PCHEs by 10 years. In fact HEXCES’ platelet technology is traceable to its invention in the mid-1960s. HEXCES personnel have been developing CPHXs for over 35 years and have a combined experience in platelet device design, analysis, manufacture, and test in excess of 200 years.

HEXCES, through its parent company Clean Energy Systems, Inc., holds the following certifications: ISO 9001:2015 and ASME BPVC U and R Stamps.

-

HEXCES COMPACT DIFFUSION BONDED HEAT EXCHANGERS

Button

Benefits of the Compact Platelet Heat Exchanger

- Four to six times smaller and lighter than conventional designs such as shell-and-tube exchangers

- Reduced weight, footprint, and supporting structures allows for flexibility in deployment location, shipping, and plant layout

- Unmatched surface area per unit volume of the exchanger

- Reduced energy requirement and cost due to high thermal effectiveness

- Exceptionally high heat transfer coefficients achievable with small-hydraulic diameter flow passages

- Extremely low fluid inventory

- High pressure capability, in excess of 600 bar

- Wide operating temperature range from -200 to 900˚C

- Improved process design, plant layout, and processing conditions

- Can be used for gases, liquids, and/or two-phase flows

- Channels can be optimized for counter, co-, or cross flow

- Multiple fluid streams possible

- No inter-plate/inter-channel seals or gaskets required

- Inherent structural design eliminates catastrophic failure modes

- Significantly reduces vibration/cyclic failure modes

- Wide range of materials of construction possible including stainless steel, nickel and cobalt based alloys, copper, titanium, and more

- Combination of multiple materials possible